Reading Dial Gauges Worksheets

About These 15 Worksheets

These worksheets are used to help students improve their understanding and proficiency in reading and interpreting measurements from various types of dial gauges. These worksheets are typically used in educational settings that focus on physics, engineering, mechanics, and vocational training. They not only help students grasp the basics of measurement but also promote precision and accuracy in practical applications. This comprehensive guide will delve into the nature of these worksheets, the types of exercises they include, and the skills they aim to develop in students.

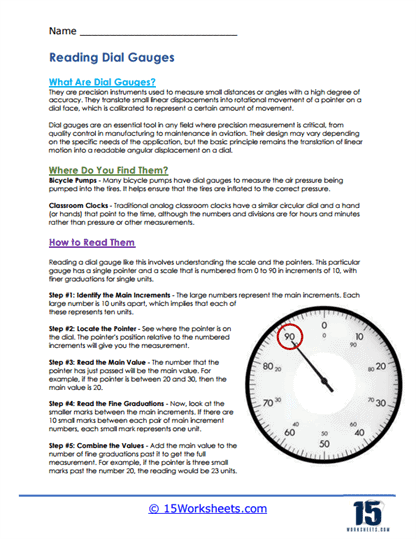

A dial gauge, also known as a dial indicator, is a precision instrument used to measure small distances or angles. It translates small linear distances into rotational movement and displays the measurement on a circular dial. Dial gauges are indispensable in the fields of engineering and mechanics where precise measurements are critical. They can vary in design but commonly include a needle or pointer that moves over a graduated scale.

Through a variety of exercises, these worksheets prepare students to engage with technical tasks confidently and accurately, reinforcing skills that are essential in many engineering and technical disciplines. By working through these worksheets, students not only master the use of dial gauges but also cultivate a meticulous approach to measurement that can be applied in numerous scientific and practical contexts.

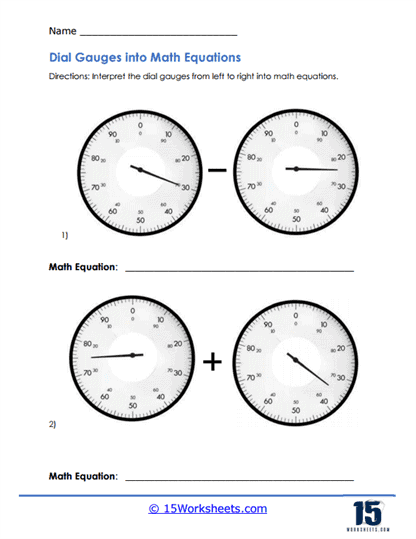

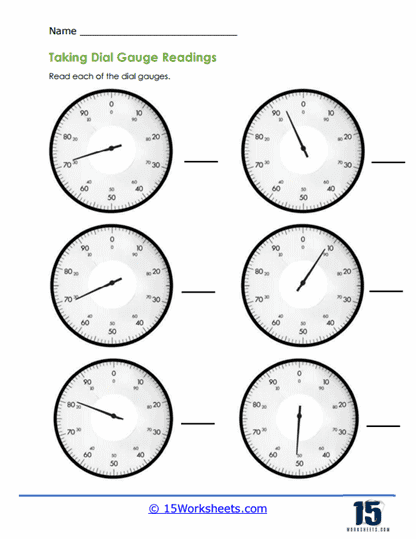

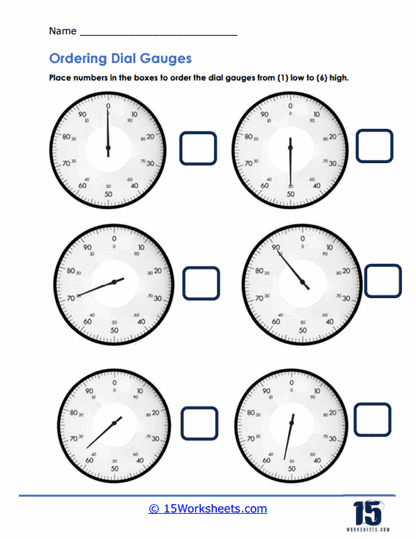

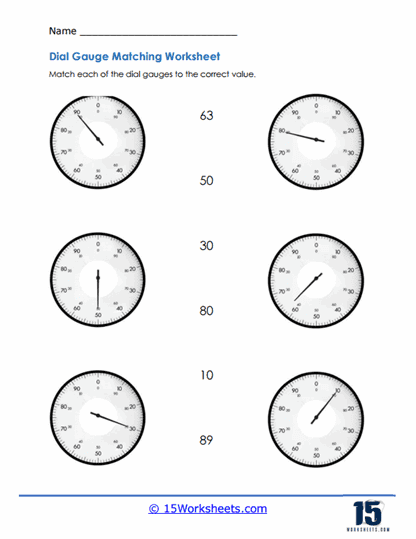

Types of Exercises

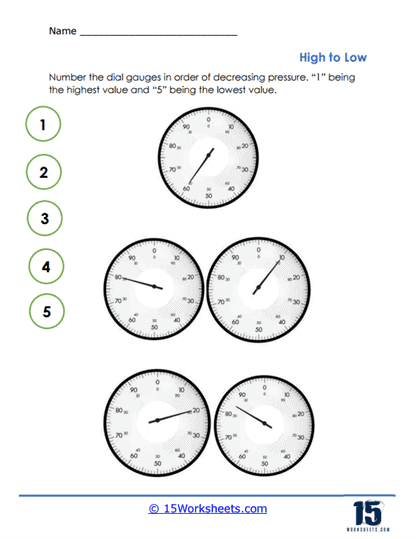

The exercises on reading dial gauges worksheets are diverse, aiming to cover a range of skills from basic reading to complex application and problem-solving. Here’s a look at some common types of exercises found on these worksheets:

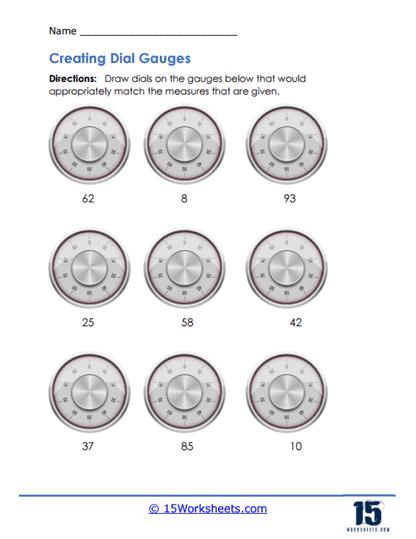

Identification Exercises – Students start with identifying the main components of a dial gauge. This may include labeling parts such as the dial, needle, face, scale, and bezel. Understanding these components is essential for correctly reading and using the instrument.

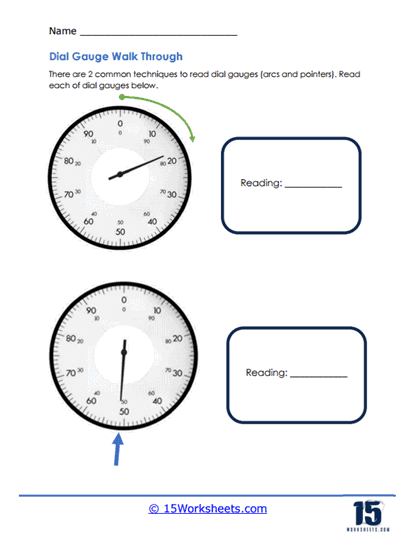

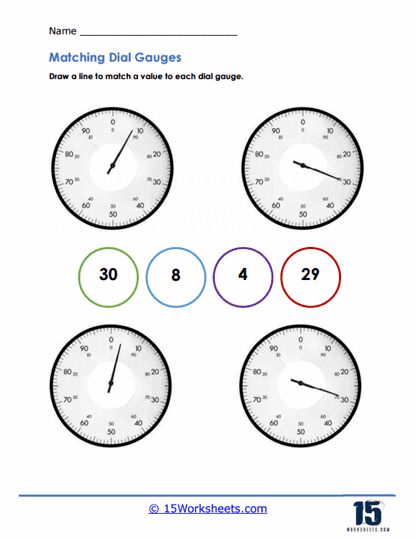

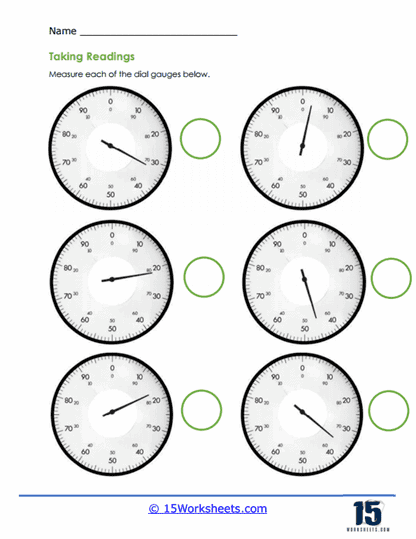

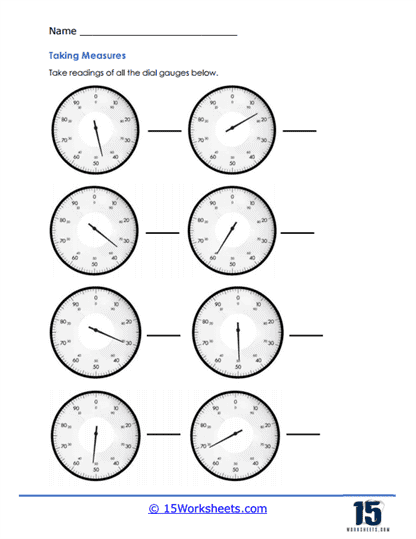

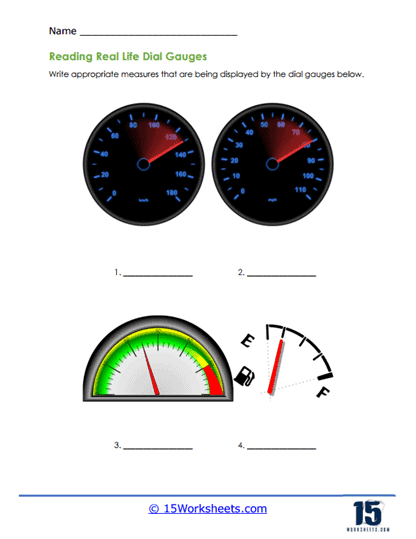

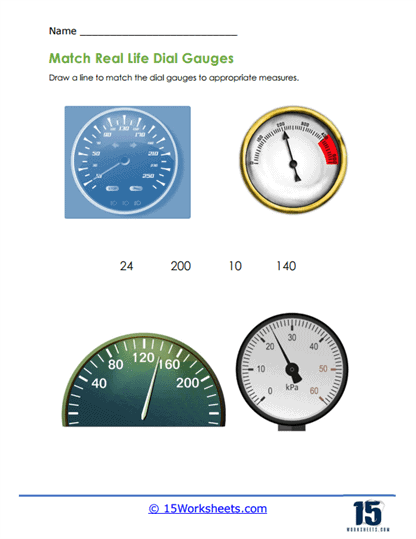

Reading Simple Measurements – These exercises focus on teaching students to read the measurements displayed by the dial gauge accurately. Typically, worksheets will present several images of dial gauges with different readings, and students must note the correct measurement. This practice develops their ability to read and interpret mechanical measurements precisely.

It’s crucial for students to understand the scale increments of a dial gauge as these can vary between tools. Exercises often require students to calculate the value of minor and major increments on different gauges, enhancing their attention to detail and mathematical skills.

Setting Zero – Learning to calibrate or set zero on a dial gauge is a fundamental skill. Worksheets may include exercises where students must determine the necessary adjustments to set the dial gauge to zero, simulating real-world applications where accurate measurement begins with proper calibration. These exercises ask students to compare measurements from multiple dial gauges to determine differences or errors. This type of exercise helps students understand how to use dial gauges for quality control and testing purposes.

Error Detection and Correction – Students are given scenarios with potential errors in reading or setting dial gauges. They must identify and correct these errors, which promotes critical thinking and a deeper understanding of how dial gauges function and how their readings can be influenced by various factors.

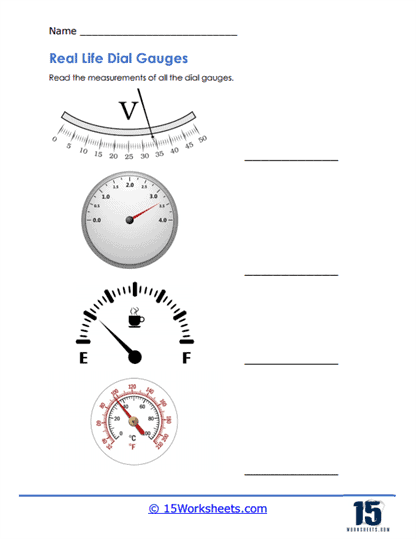

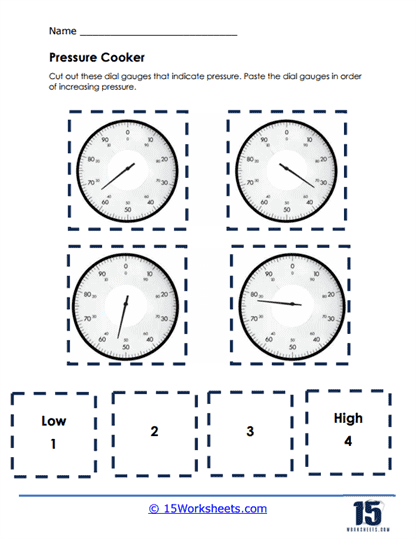

Practical Application Scenarios – To bridge theory with practical application, worksheets often include scenarios where students must apply their knowledge of dial gauges to solve real-world problems. For example, they might use readings from a dial gauge to determine if a surface is perfectly flat or if a machine part is within specified tolerance levels. For more advanced students, exercises might involve interpreting dial gauge readings in the context of statistical process control or engineering tolerances. These exercises can be quite complex, involving multiple steps and calculations, to ensure parts are produced within acceptable limits.

Where Are Dial Gauges Commonly Used?

Dial gauges are critical in any field where precision is a prerequisite. They provide accurate measurements that are essential for quality control, safety, and efficiency. Whether it’s in ensuring that a jet engine runs smoothly or a car’s wheels are aligned, dial gauges play a fundamental role in maintaining the high standards required in today’s technological and engineering advancements. Their use spans across industries, showcasing their versatility and indispensability in modern technical environments.

In everyday life, people frequently encounter and use dial gauges in various forms, often without realizing the critical role these instruments play. Here are some common scenarios where dial gauges are used regularly:

1. Automobiles

Tire Pressure Gauges – One of the most common uses of dial gauges in daily life is checking tire pressure. Many drivers use dial tire pressure gauges to ensure their vehicle’s tires are inflated to the correct pressure, which is crucial for safe driving, optimal tire performance, and fuel efficiency.

Dashboard Instruments – Cars feature a range of dial gauges on the dashboard, including the speedometer, tachometer, fuel gauge, and temperature gauge. These provide drivers with vital information about the vehicle’s speed, engine RPM, fuel level, and engine temperature.

2. Home Appliances

Ovens and Stoves – Dial gauges are used to set temperatures on many types of kitchen appliances. Ovens, for instance, often have a dial to control the temperature, ensuring that food is cooked at the correct setting.

Pressure Cookers and Canners – These often feature a dial gauge to monitor the pressure inside the cooker, crucial for cooking food properly and safely.

3. HVAC Systems

Pressure Gauges in Heating Systems – Dial gauges are commonly found in residential and commercial heating systems, including boilers and hot water systems. These gauges monitor the pressure and sometimes the temperature to ensure the system operates safely and efficiently.

Air Conditioning Units – Similarly, dial gauges are used to check pressure levels during the maintenance and setup of air conditioning units, helping to diagnose issues and ensure proper functionality.

4. Gardening and Landscaping

Water Pressure Gauges – Dial gauges are used on irrigation systems and garden hoses to monitor water pressure, which helps in maintaining the health of plants and efficiency of the watering system.

5. Sporting Equipment

Scuba Diving – Divers use a submersible pressure gauge, a type of dial gauge, to monitor the amount of air remaining in their tanks. Accurate readings are essential for safe diving practices.

Bicycles – Bicycle pumps often come with a built-in dial gauge to help cyclists inflate their tires to the optimal pressure for the type of riding they are doing.

6. Healthcare

Blood Pressure Monitors – Manual blood pressure monitors (sphygmomanometers) often use a dial gauge to provide a reading of blood pressure. This is a common practice in both medical facilities and homes where individuals monitor their own blood pressure.

7. Industrial and Workshop Tools

Air Compressors – Many workshops use air compressors equipped with dial gauges to monitor and regulate air pressure. This is crucial for powering pneumatic tools accurately and safely.